Carbon Fiber also known as graphite fiber is a subset of the polymers market. They are composed of long, thin, and crystalline filaments of carbon that are used to strengthen materials. Carbon fiber has a high chemical and thermal resistance, in addition to low thermal expansion. The material is lightweight and is five times stronger than steel. Therefore, carbon fiber has a high strength-to-weight ratio, in addition to increased stiffness that promotes its use to fabricate parts of machinery.

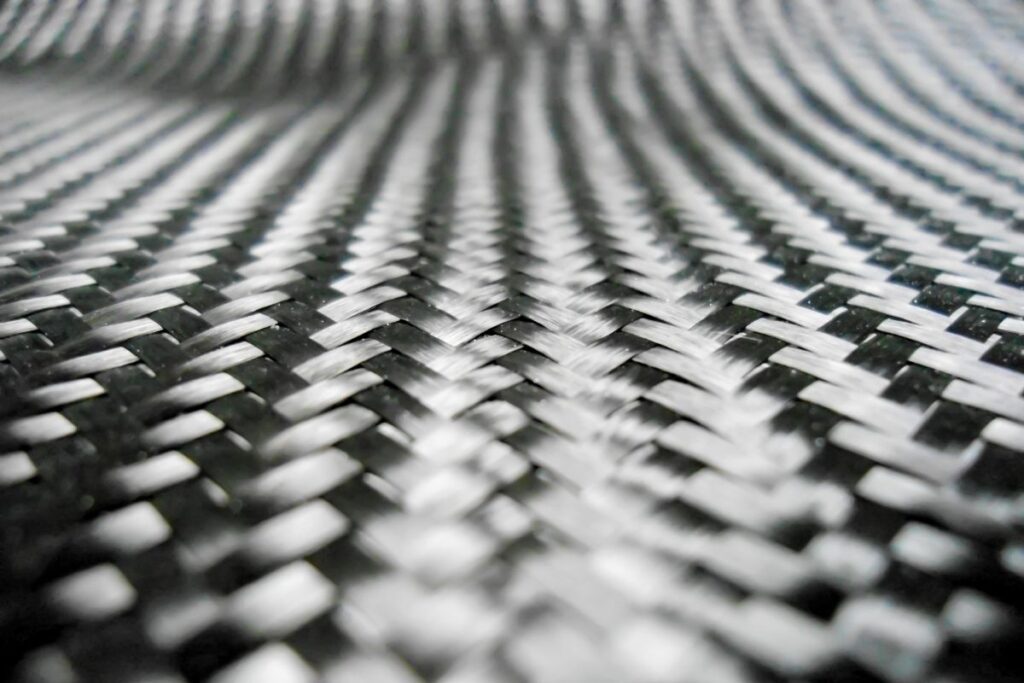

Carbon fiber is often woven since the material is stronger when twisted like yarn. The material can be used in a cloth format in applications where flexibility is a key criterion. To form a permanent shape, carbon fiber can be laid over the required mold and coated in plastic or resin.

The process used for the production of Carbon Fiber

Growth in material science engineering is one of the key drivers for this market. Carbon fiber is typically made from a process that is both chemical and mechanical. The process is initiated by drawing long strands of fiber and heating the same to a very high temperature. The heating is performed in a vacuum environment to prevent the burning of the fibers. The vacuum combustion leads to the carbonization of the material. The carbon atoms within the material vibrate vigorously thus expelling most of the non-carbon atoms. The product generated through this process is a fiber composed of long carbon chains with tight interlocking on a molecular level.

Applications

Carbon Fiber has been used to make Bike Frames, Aircraft Wings, Automotive drive shafts, Tubing, Containers, Propelled blades, and Car components. The material accounts for a key segment of the automotive sector globally. Other counterparts of the value chain for carbon fiber include the aircraft and aerospace industry, wind energy sector, as well as the automotive industry with optimized resin systems.

Carbon Fiber for Cars

Most car components are composed of steel. Replacing steel with carbon fiber would reduce the weight of the automotive system by roughly 60%. The reduced weight of the vehicle would decrease the fuel consumption of the vehicle by roughly 30%. Thin in turn would reduce carbon emission associated with the vehicle by roughly 10-20%. Reducing the weight of the automotive system would hereby promote sustainable practices. The increased adoption of green technology would help the environment achieve a circular economy. However, on making a trade-off study it is seen that carbon fiber is more cost-intensive as compared to steel. The material is roughly 10-12x more expensive as compared to steel.

Composites are gaining popularity within the automotive sector. Due to the cost of the material, carbon fiber was mainly used for high-end applications previously. For instance, carbon fiber was used to construct the framework for specialty cars and sports vehicles. Carbon fiber for cars is structurally rigid. Moreover, the material is mouldable. It can also reduce the number of components to be manufacture.

Carbon fiber as a material is popular within the race car sector. This is major because race cars produce large quantities of heat. Carbon fiber has low thermal conductivity. Moreover, the material has low thermal expansion. Therefore, carbon fiber for cars used in the racing industry manages the heat of the system and maintains the same at room temperature. Hence high amounts of heat liberated by race cars do not denature the structural integrity of the automotive system.

Carbon Fiber Hydro Drip

Hydro drip is the process used to generated imprints or graphics on a structure. This method is widely used within the automotive industry. Carbon fiber hydro drip provides cutting-edge graphical designs for the existing automotive systems. Carbon fiber hydro drip provides the automotive system with a carbon look that is also long-lasting. The designs that are to be applied to the 3D structure are printed on a film. The carbon film has intricate designs on it in the form of diagonal lines.

Carbon Fiber as a part of the Material Science Industry

In terms of material science, carbon fiber is mainly used to reinforce compounds like composites. Carbon Reinforced Graphite is one such example. The material is usually used in high-temperature applications. Carbon Reinforced Graphite is used as an anti-static in industries and for the filtration of high-temperature gases.

Carbon Fiber is also used in the textile industry for operations such as filament winding, weaving, braiding, etc. The yarn is used to weave carbon fiber filaments or cloths.

In terms of industrial applications, carbon fiber is used to fabricate electrodes as well. The applications for these electrodes are either in amperometry or fast-scan cyclic voltammetry. They are employed in research experiments to study and detect biochemical signaling.